Quality-enhanced Power Semiconductor Devices for Reliable Energy Conversion

Project Duration: Nov 2020 – Oct 2024

PhD Student: Manuel Belanche Guadas (LinkedIn)

Principal Investigator: Prof. Ulrike Grossner, Advanced Power Semiconductor Laboratory, Department of Information Technology and Electrical Engineering, ETH Zurich, Switzerland

Project Partner: Florian Krippendorf, mi2-factory GmbH, Jena, Germany

Research Fields: Semiconductor Physics, Wide-bandgap Electronics.

Project Description

Power semiconductor devices are a fundamental part of the power electronics that compose all electrical energy systems required in society. From renewable energy generation to electric vehicles and power supplies markets, power semiconductor devices can strongly contribute to the reduction of global energy loss and improvement in power management. Along with the emergence during the last two decades of such markets, a remarkable amount of R&D was conducted in the field of power electronics providing solutions for the increasing semiconductor devices requirements.

However, with increasing demands on performance and efficiency, traditional Si-based devices have reached their performance limits. Consequently, a migration to more robust semiconductor materials is necessary. Wide-bandgap semiconductors, e.g., Silicon Carbide (SiC), are emergent viable alternative given their superior electrical properties. However, SiC-based semiconductor technology is rather young and hence comprehensive understanding of its electrical behavior and an improvement in device quality and reliability is needed.

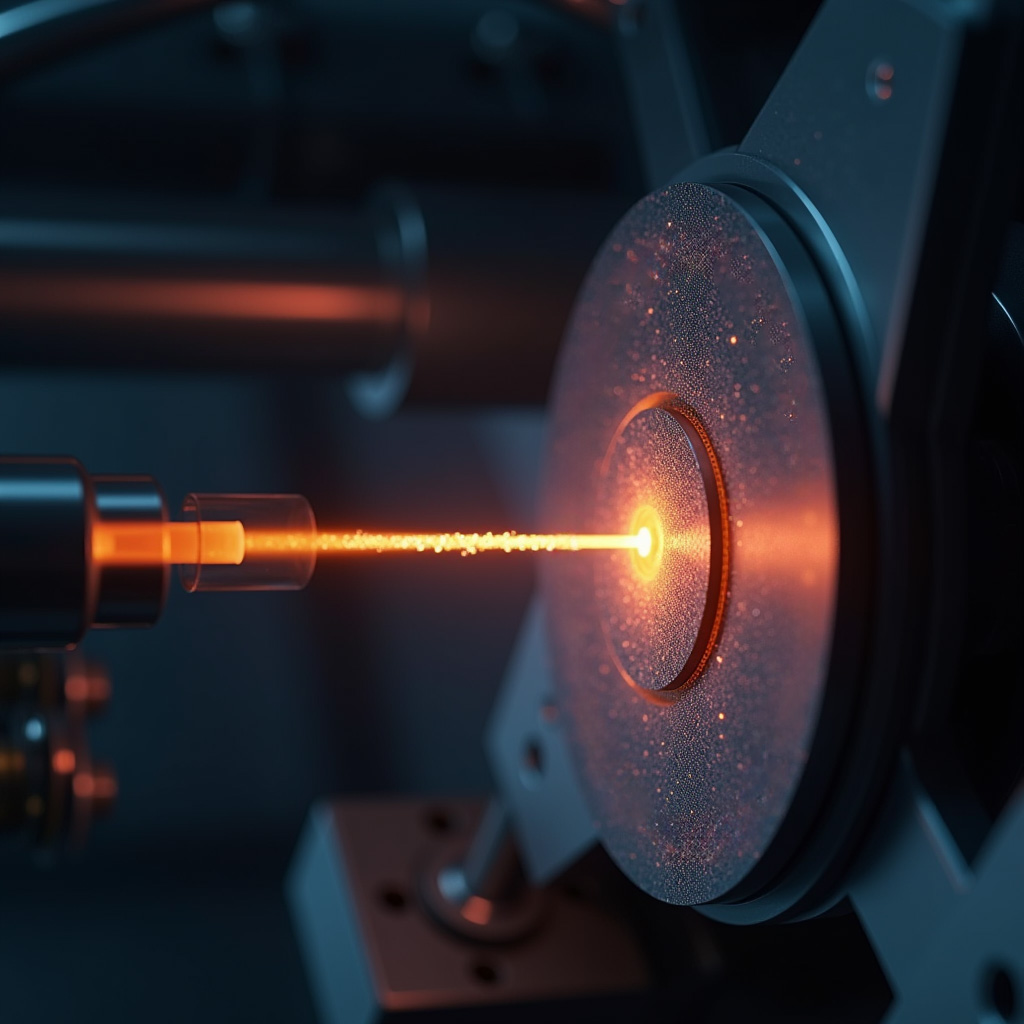

The aim of the project is the development of novel ion-implantation technology to realize SiC-based super junction devices, designated to outperform the existing wide-bandgap semiconductor devices. In collaboration with mi2-factory GmbH, given their state- of-the-art energy filters technology, the focus will be on the ion implantation process as a key process for the fabrication of efficient and reliable high-voltage devices. The modelling of super junction device structures, in addition to the development of adequate fabrication technologies, will eventually allow the prototyping of high quality and reliable super junction structures based on Silicon Carbide.

This fellowship is hosted by the Energy Science Center.

Activities and Publications

Doctoral thesis (ongoing)

PSC Blog article (2025) Next-Generation Semiconductor Materials for Sustainable Energy Transition

Peer-reviewed article in Materials Science in Semiconductor Processing (2024) on Aluminum channeling in 4H-SiC by high-energy implantation above 10 MeV

Peer-reviewed article in IEEE Transactions on Nuclear Science (2023) on Investigation of Electrically Active Defects in SiC Power Diodes Caused by Heavy Ion Irradiation

Peer-reviewed conference paper in Defect and Diffusion Forum (2023) on Minority Carrier Traps Induced by Neutron Reactions with 4H-SiC

Peer-reviewed conference paper in Materials Science Forum (2022) on Sensitivity of Dit Extraction at the SiO2/SiC Interface Using Quasi-Static Capacitance-Voltage Measurements

Conference talk at the International Conference on Silicon Carbide and Related Materials (ICSCRM, Raleigh, USA, Sept 2024)

Conference poster and talk at the International Conference on Silicon Carbide and Related Materials (ICSCRM, Sorrento, Italy, Sept 2023)

Conference poster at the 19th International Conference on Silicon Carbide and Related Materials (ICSCRM 2022, Davos, Switzerland, Sept 2022)

Conference talk at the 13th European Conference on Silicon Carbide and Related Materials (ECSCRM 2020-2021, Tours, France, Oct 2021)

Industry Fair - Participation with mi2-factory (RESPONSE partner) in PCIM Europe 2023 Industry Fair: Further sustainability focus in power electronics (Nuremberg, Germany, May 2023)

Secondment

The secondment at mi2-factory focused on the energy filtered ion implantation technology, being developed at the company for the fabrication of charge-balanced power devices. The primary focus of Manuel’s research was to study the influence of the ion implantation hard mask, particularly in terms of angle, thickness, and aspect ratio, on the distribution of dopants within silicon carbide. This investigation is crucial, as these factors significantly affect the precision and success of the implantation process, leading to better-performing power devices. This research relied on simulations using the Geant4 software, which was calibrated with energy filtered implantations performed at the Helmholtz-Zentrum Dresden-Rossendorf research laboratory. This allowed to model and predict how changes in the mask parameters would impact the dopant distribution, helping to optimize the overall implantation process. The time at the company allowed Manuel to work closely with a team of experts, gain practical experience in the field, and apply theoretical knowledge to industry applications. The insights gained from this stay will contribute to the ongoing development of advanced power devices, and will be discussed in coming publications.

Duration: Feb 2022 – May 2022

Stakeholder Workshop

The workshop titled “Development of implantation technology for high-voltage SJ (super junction) structure” brought together the main stakeholders to discuss the research outcome as well as to further align each of stakeholder’s goals and interests. The workshop was carried out during the International Conference on Silicon Carbide and Related Materials (ICSCRM, Sep 17-22, 2023) on Sep 18 – 19, 2023 in Sorrento, Italy. At total of 12 people from Advanced Power Semiconductor Lab ETH Zurich, mi2-factory (Jena, Germany, RESPONSE partner), National Institute of Advanced Industrial Science and Technology (Tsukuba Japan), Central Research Institute of Electric Power Industry (Yokosuka, Japan), Nagoya Institute of Technology (Nagoya, Japan) and Kyoto University (Kyoto, Japan) were actively participating. Together with Yoshiyuki Yonezawa from AIST, Manuel organized and moderated the discussions that were following input talks of different stakeholders. In total, 4-5 hours of discussion were distributed throughout the two days. Thanks to the available time together and the in-person meeting, Manuel was able to not only have a broad discussion of the project progress but also to discuss some topics in high detail. This engagement as well as the discussions helped Manuel to reflect on the research carried out until this event and to understand what next steps will be more relevant for the development of Silicon Carbide super junction technology. Moreover, all participants were very satisfied, which helped to build a closer network highly relevant for gathering new input directing the next steps in his project and establishing new collaborations.